More cars are coming through the workshop with radar sensors, forward-facing cameras, and ADAS features built into bumpers, windscreens, and mirrors. If you are not thinking about calibration after repairs, your workshop may be taking on more risk than you realise.

Here is what every technician and panel shop needs to know about ADAS calibration and why it matters more than ever.

What Is ADAS Calibration?

Calibration is the process of aligning and verifying the accuracy of advanced driver assistance systems.

These systems include:

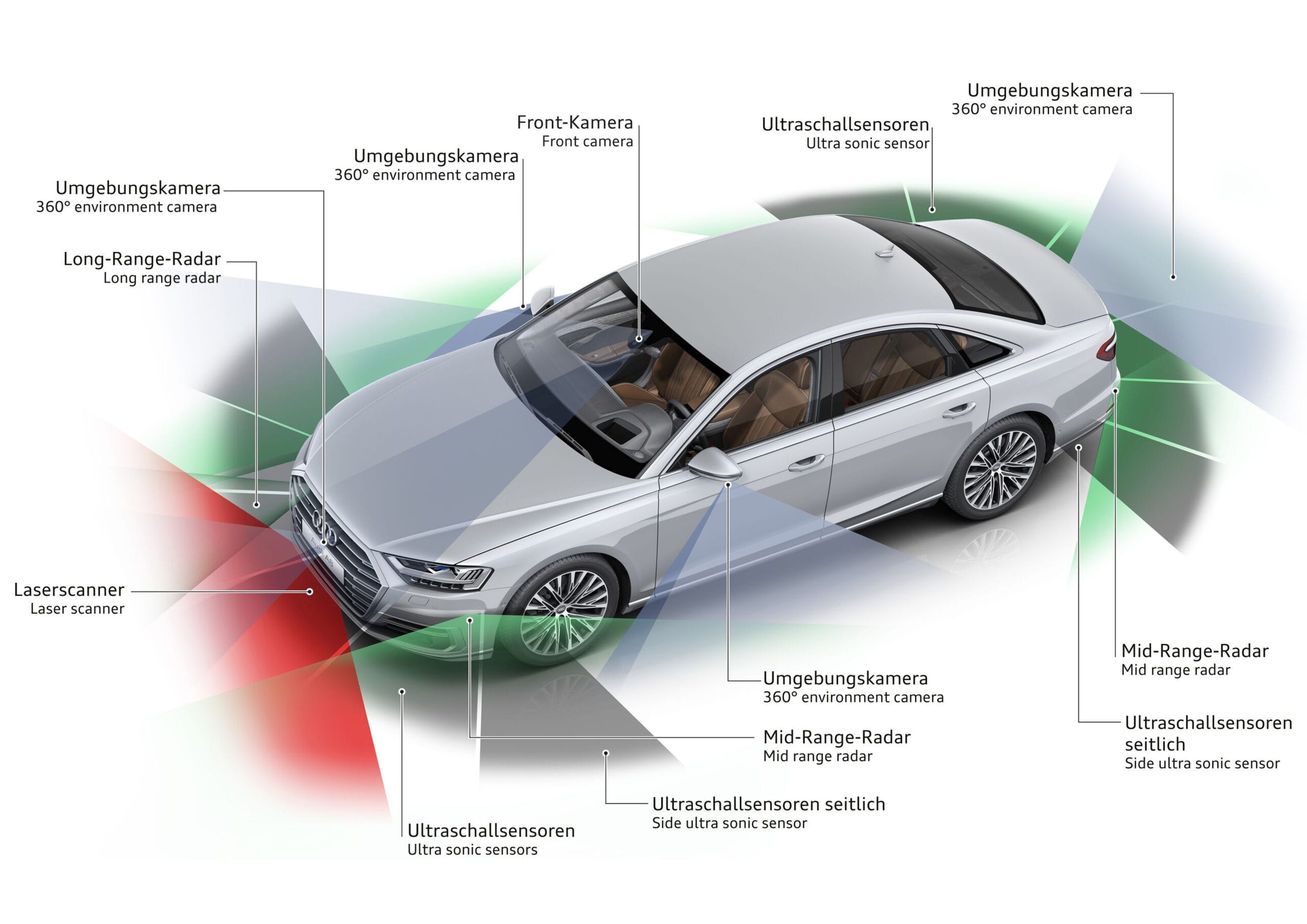

- Forward-facing cameras

- Radar and LiDAR sensors

- Surround-view cameras

- Blind spot modules

Each sensor has to be correctly positioned, aimed, and tested. Even a small shift in a camera angle or radar pitch can cause:

- False readings

- Failure to warn

- Delayed braking

- Lane keep drift

- Incorrect blind spot alerts

This is not just a comfort issue. It is a safety issue.

When Is Calibration Required?

A calibration is usually required after any job that affects:

- Windscreens Bumpers (front or rear)

- Suspension or ride height

- Wheel alignment

- Steering rack or tie rods

- Panel replacement around sensor zones

- Wiring repairs or module replacements

Even small knocks or parts swaps can alter how a sensor reads the environment.

Some of these are OEM dependent. Always refer to the manufacturer instructions specific for the vehicle you are working on.

Static vs Dynamic Calibration

There are two main types of calibration:

- Static calibration uses physical targets and laser tools in a controlled space

- Dynamic calibration requires driving the car at a set speed under certain conditions

Some vehicles require both. If you are not set up to handle either method, you may need to refer the vehicle out to a specialist.

Why It Matters for Safety and Liability

If a vehicle’s ADAS system fails after a repair and no calibration was performed or documented, the shop may be liable.

Most OEMs now recommend post-repair scanning and calibration where applicable. Insurers are increasingly asking for evidence too.

A misaligned camera or radar is not always visible to the driver until the system fails. That makes documentation and verification essential.

Final Tip

If your shop is not checking ADAS calibration requirements as part of the repair process, now is the time to start. Build it into your job cards. Talk to glass and panel suppliers. Know which systems trigger the need for recalibration.

It only takes one incident to turn a routine repair into a major liability.

For more resources, visit our Calibration Club.

Hiran Alwis is an automotive lecturer and ADAS specialist with over 15 years of experience in diagnostics, advanced safety systems, and technical training. He founded ADAS Project to help everyday drivers and workshop technicians understand and safely use advanced driver assistance systems.