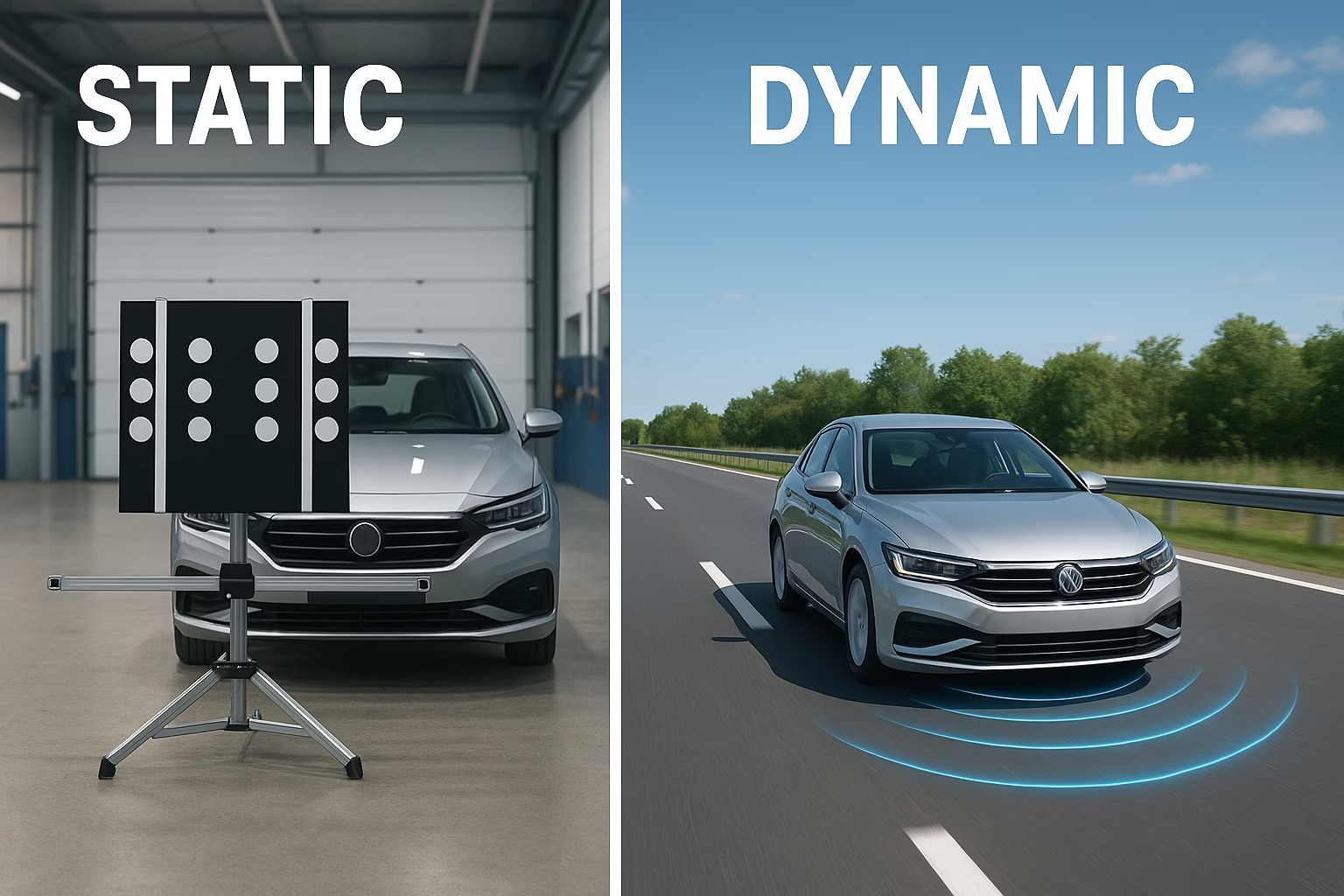

Advanced driver assistance systems (ADAS) use cameras, radar and sometimes LiDAR to monitor a vehicle’s surroundings, but those sensors need to be precisely calibrated. After a bumper is replaced or a windscreen is changed, the sensors may no longer point where they should. Calibration realigns them so that features like lane departure warning or adaptive cruise control respond at the right moment. There are two main calibration methods: static and dynamic.

Static calibration

Static calibration is performed in a controlled workshop environment. The vehicle is parked on a level surface and specialist equipment such as calibration targets, radar reflectors, infrared panels and wheel alignment stands is set up at precise distances . This allows the technician to recalibrate forward-facing cameras or radar sensors even when the car is stationary. Static calibrations are typically used after windscreen replacement, front bumper repairs, suspension work or when multiple sensors need to be aligned simultaneously . They require adequate workshop space, accurate equipment and a clean, well-lit area. Because the targets can replicate lane lines and objects, the sensors learn their reference points before the vehicle moves.

Dynamic calibration

Dynamic calibration takes place while the car is being driven on the road. A diagnostic tool is connected to the vehicle and instructs the driver to accelerate to a specific speed so that the sensor can learn lane markings and traffic . Dynamic calibrations are common for radar-based systems like adaptive cruise control and lane keep assist. They are quicker because there is no need to set up targets, but they rely on good weather, clear lane markings and light traffic. As Modern Tire Dealer notes, dynamic calibration can often be done by a single technician with a scan tool and road test . However, if the roads are wet or the lane lines are faded, the calibration may fail and a static method will be required.

How to know which one applies

The vehicle manufacturer’s service information will specify which sensors need to be calibrated and whether a static or dynamic procedure is required. In general, forward-facing cameras mounted to the windscreen will require static calibration after replacement because the camera’s relationship to the vehicle must be reset . Radar units behind the bumper may use dynamic calibration after a minor repair. Many vehicles require both: a static calibration to set reference points and then a dynamic calibration to fine-tune the system on the road.

Signs that calibration is needed include dashboard warning lights, ADAS features not functioning or interventions that occur too earAdvanced driver assistance systems (ADAS) use cameras, radar and sometimes LiDAR to monitor a vehicle’s surroundings, but those sensors need to be precisely calibrated. After a bumper is replaced or a windscreen is changed, the sensors may no longer point where they should. Calibration realigns them so that features like lane departure warning or adaptive cruise control respond at the right moment. There are two main calibration methods: static and dynamic.

Static calibration

Static calibration is performed in a controlled workshop environment. The vehicle is parked on a level surface and specialist equipment such as calibration targets, radar reflectors, infrared panels and wheel alignment stands is set up at precise distances . This allows the technician to recalibrate forward-facing cameras or radar sensors even when the car is stationary. Static calibrations are typically used after windscreen replacement, front bumper repairs, suspension work or when multiple sensors need to be aligned simultaneously . They require adequate workshop space, accurate equipment and a clean, well-lit area. Because the targets can replicate lane lines and objects, the sensors learn their reference points before the vehicle moves.

Dynamic calibration

Dynamic calibration takes place while the car is being driven on the road. A diagnostic tool is connected to the vehicle and instructs the driver to accelerate to a specific speed so that the sensor can learn lane markings and traffic . Dynamic calibrations are common for radar-based systems like adaptive cruise control and lane keep assist. They are quicker because there is no need to set up targets, but they rely on good weather, clear lane markings and light traffic. As Modern Tire Dealer notes, dynamic calibration can often be done by a single technician with a scan tool and road test . However, if the roads are wet or the lane lines are faded, the calibration may fail and a static method will be required.

How to know which one applies

The vehicle manufacturer’s service information will specify which sensors need to be calibrated and whether a static or dynamic procedure is required. In general, forward-facing cameras mounted to the windscreen will require static calibration after replacement because the camera’s relationship to the vehicle must be reset . Radar units behind the bumper may use dynamic calibration after a minor repair. Many vehicles require both: a static calibration to set reference points and then a dynamic calibration to fine-tune the system on the road.

Signs that calibration is needed include dashboard warning lights, ADAS features not functioning or interventions that occur too early or too late. The Activate Group warns that sensors knocked out of position in minor collisions or repairs can cause safety features to stop working or intervene unnecessarily . Technicians should always check wheel alignment first because misaligned wheels will throw off sensor angles . After the alignment is complete, they can follow the manufacturer’s instructions for the appropriate calibration type.

Summary

Both static and dynamic calibrations play an essential role in ensuring ADAS functions correctly. Static calibration provides a controlled environment to reset camera and radar angles using targets and specialised tools. Dynamic calibration fine‑tunes the system on real roads by letting sensors learn lane lines at speed. With the rapid growth of ADAS and the proliferation of sensor types, workshops must equip themselves to perform both methods. Correct calibration not only restores safety features but also protects workshops from liability if an uncalibrated vehicle’s ADAS fails in the field . When in doubt, consult service manuals or partner with a specialist calibration provider to ensure that every vehicle leaves your workshop with its driver assistance systems working as intended.ly or too late. The Activate Group warns that sensors knocked out of position in minor collisions or repairs can cause safety features to stop working or intervene unnecessarily . Technicians should always check wheel alignment first because misaligned wheels will throw off sensor angles . After the alignment is complete, they can follow the manufacturer’s instructions for the appropriate calibration type.

Summary

Both static and dynamic calibrations play an essential role in ensuring ADAS functions correctly. Static calibration provides a controlled environment to reset camera and radar angles using targets and specialised tools. Dynamic calibration fine‑tunes the system on real roads by letting sensors learn lane lines at speed. With the rapid growth of ADAS and the proliferation of sensor types, workshops must equip themselves to perform both methods. Correct calibration not only restores safety features but also protects workshops from liability if an uncalibrated vehicle’s ADAS fails in the field . When in doubt, consult service manuals or partner with a specialist calibration provider to ensure that every vehicle leaves your workshop with its driver assistance systems working as intended.

Hiran Alwis is an automotive lecturer and ADAS specialist with over 15 years of experience in diagnostics, advanced safety systems, and technical training. He founded ADAS Project to help everyday drivers and workshop technicians understand and safely use advanced driver assistance systems.