Introduction

Advanced driver assistance systems rely on sensors and cameras that must be calibrated precisely. Performing these calibrations in an improvised space can lead to inconsistent results and wasted time. A dedicated calibration station provides a controlled environment, improves workflow and projects professionalism. This guide outlines how to set up an efficient ADAS calibration station.

Why a Dedicated Calibration Station Matters

Having a proper station isn’t just about aesthetics—it directly affects accuracy and efficiency. Key benefits include:

- Consistent measurements – A flat, level surface eliminates variability caused by uneven floors.

- Improved workflow – Keeping calibration tools, targets and measurement devices in one zone reduces setup time and confusion.

- Safe environment – A dedicated space reduces trip hazards and keeps sensitive sensors away from shop dust and traffic.

- Professional impression – Clients and insurers see that you treat ADAS work with seriousness, building trust in your services.

Choosing the Right Space

Select a bay with ample room around the vehicle. The area should allow you to position targets at the required distances without obstruction. Floors must be level; minor slopes can introduce errors. Good overhead lighting is essential for cameras to read targets, and walls painted in neutral colours minimize reflections. Ensure there are convenient power outlets for laptops and diagnostic tools. Avoid placing the station near busy walkways to reduce accidental bumps.

Climate control matters too. Sensors operate best within manufacturer‑specified temperature ranges. If your workshop experiences extreme temperatures, consider portable heaters or air conditioners to keep the calibration bay stable.

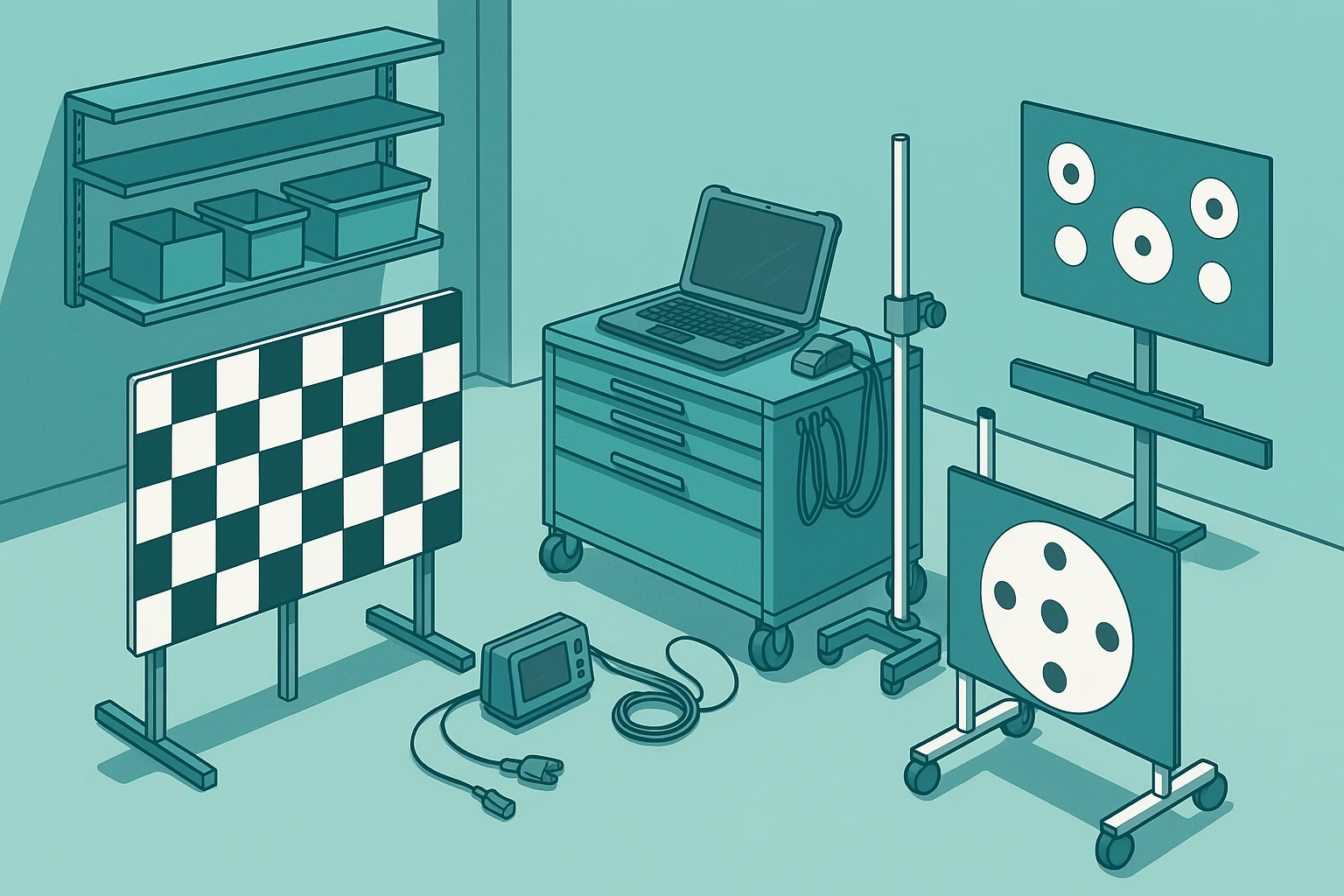

Essential Tools and Equipment

Outfitting your station properly helps avoid delays and ensures you can handle a variety of vehicles. Core items include:

- Calibration frames and target panels – Specific patterns for radar, camera and LiDAR systems. Keep them in protective cases to prevent warping.

- Diagnostic scan tool – Capable of performing calibrations and initiating sensor alignments.

- Laser alignment devices or wheel alignment stands – Help ensure the vehicle sits squarely in the bay.

- Precision measuring tools – Rulers, tape measures and digital inclinometers for verifying target heights and distances.

- Stable stands and fixtures – Adjustable mounts for holding targets at the correct orientation and height.

- Laptop or workstation – Used to run calibration software, check service manuals and record data.

- Cable reels and chargers – Keep power cords tidy and avoid tripping hazards.

Invest in quality equipment from reputable suppliers. Using manufacturer‑approved targets and tools helps avoid issues with accuracy or warranty claims.

Organising Your Station

Efficiency depends on how well your tools are stored. Install shelving or cabinets for target panels and small parts. Use labelled bins for bolts, clips and adapters. Keep a rolling tool cart stocked with frequently used items so you can move around the vehicle without leaving the bay. Coil cables neatly and secure them with cable ties or retractable reels to keep the floor clear. A tidy workspace not only speeds up work but also reduces the risk of damaging sensitive equipment.

Environmental Factors

Light and cleanliness play major roles in calibration accuracy. Use bright, even lighting—avoid strong shadows or glare. If natural light through windows is unavoidable, install blinds or curtains to control reflections. Maintain a dust‑free environment by sweeping regularly and avoiding sanding or grinding in nearby bays. Good ventilation ensures fumes from adhesives or solvents don’t build up, which can affect both technician health and sensor performance.

Tips for Efficiency

To make your calibration station productive:

- Develop checklists – Pre‑calibration and post‑calibration lists help ensure no step is missed.

- Standardize equipment settings – Mark floor positions for targets and stands to speed up setup.

- Routine maintenance – Inspect targets for damage and clean them regularly. Calibrate your measuring tools per manufacturer guidelines.

- Stay updated – Software updates for diagnostic tools add new models and fix bugs. Schedule time to update regularly.

- Train all staff – Consistency comes from everyone following the same procedures. Encourage knowledge sharing and continuous improvement.

Summary

Building a dedicated calibration station is an investment in quality and safety. A well‑chosen space with appropriate lighting, level floors and climate control reduces variables that can affect sensor alignment. Stocking the right tools and organising them thoughtfully speeds up work and safeguards equipment. By maintaining a clean, orderly environment and following structured processes, technicians can deliver accurate calibrations efficiently. Establishing this professional space will help your workshop handle the growing demand for ADAS services with confidence and precision.

Hiran Alwis is an automotive lecturer and ADAS specialist with over 15 years of experience in diagnostics, advanced safety systems, and technical training. He founded ADAS Project to help everyday drivers and workshop technicians understand and safely use advanced driver assistance systems.